Tailor-made freezing line for poultry processing

Retrofit and Line Expansion in Poultry Processing

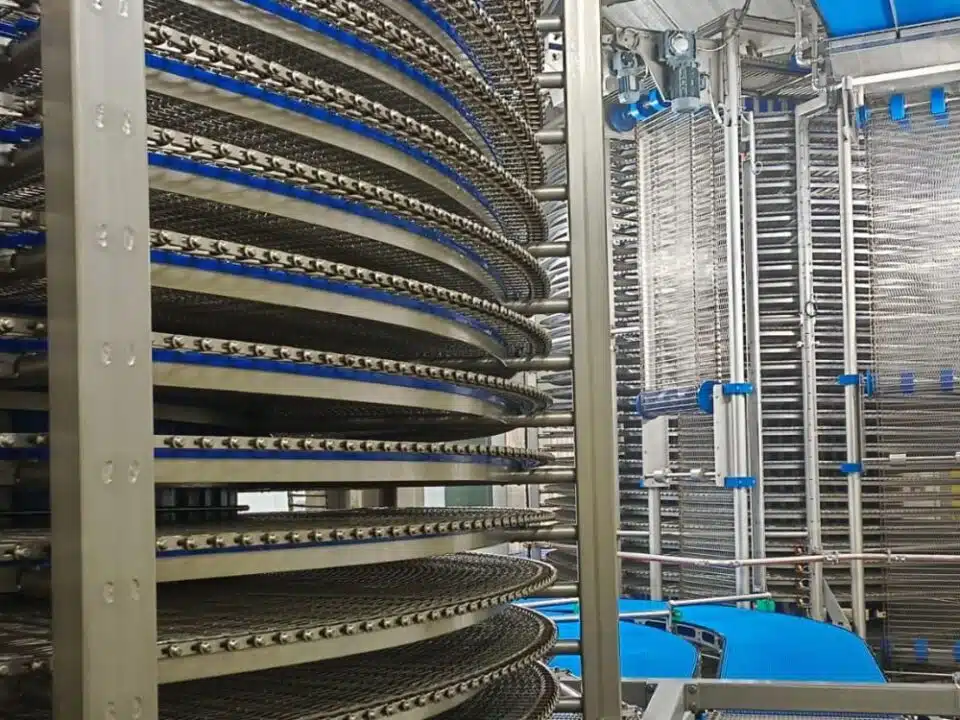

A major producer of halal chicken products in the Netherlands needed a comprehensive upgrade of their existing freezing line. Their spiral freezer showed signs of wear and required a full overhaul. At the same time, there was a technical challenge: injected chicken pieces were sticking to the belt during the freezing process.

The Challenge: Stick-Free Freezing Within an Existing Line

The goal was twofold, to fully revise the spiral freezer and to prevent the chicken pieces from sticking during freezing. This required a pre-freeze solution that could be seamlessly integrated into the current production line without sacrificing capacity or continuity.

The Solution: Full Retrofit and Contact Belt Freezer

Van Abeelen delivered both a complete technical retrofit and a belt contact freezer to pre-freeze the underside of the chicken pieces. This prevents product adhesion inside the spiral freezer and ensures a smooth production flow.

Scope of work:

- New conveyor belt, drum strips, and belt support profiles.

- New discharge unit with drive system and air guide plates.

- Integration of a belt contact freezer ahead of the spiral freezer.

- Modification of the existing control system.

- Close collaboration with the production team to optimise performance.

Result: Improved Performance and Smoother Product Flow

Thanks to the technical upgrade and the smart addition of the belt contact freezer, the line now runs more efficiently, hygienically, and with less downtime. On-site technician Jeffrey worked closely with the production leads to ensure that operating staff were properly trained and the new process was fully optimised. Van Abeelen is currently working on a follow-up project at another location for this customer.

Looking for a sustainable and flexible cooling solution?

We are happy to help you find a fast and efficient solution to your cooling challenge. Call +31 (0)161 226 597 or email us [email protected].