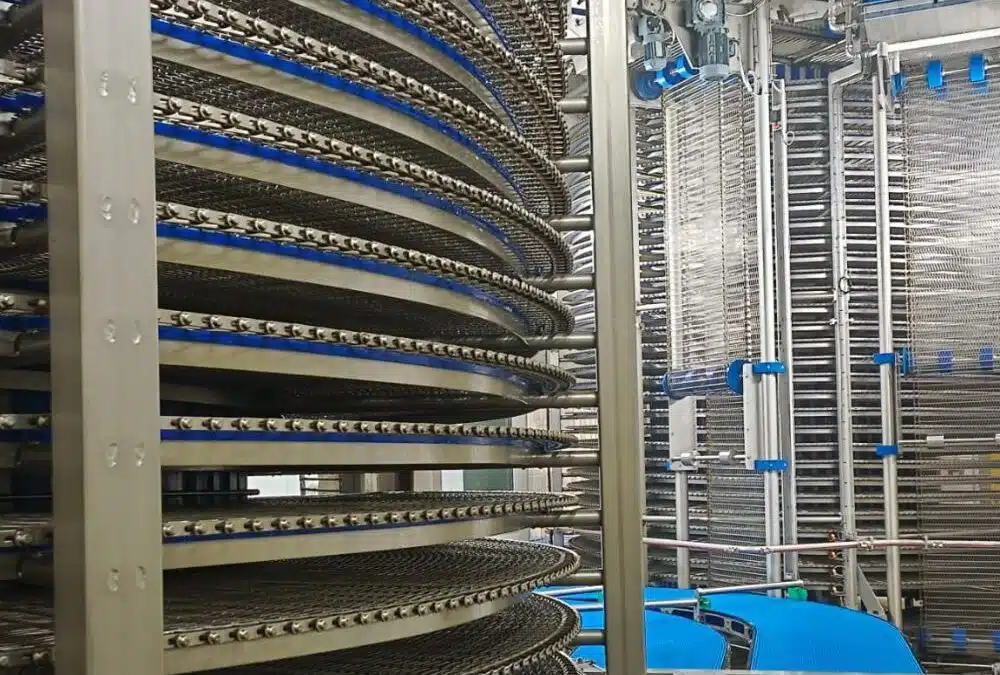

High-performance cooling solution for premium frozen products

For a German producer of hand-shaped frozen pizzas, Van Abeelen delivered a fully customised spiral cooling system. This FMCG company sets high standards: artisanal quality, sustainable production, and top-tier ingredients. In this process, the cooling installation plays a key role in safeguarding product quality.

The challenge: limited space and a tight deadline

The existing system could not sufficiently cool the pizzas, leading to a drop in quality. On top of that, space was extremely limited, making a standard installation unfeasible. The biggest challenge? The entire installation had to be up and running within just one week, integrated into the existing production process without causing downtime.

Compact, powerful, and efficient

Van Abeelen designed a tailor-made system with two spiral coolers, each equipped with dual lanes at both infeed and outfeed. This setup allows four pizza streams to be processed simultaneously, without compromising space or quality.

Key benefits:

- Four lanes in a compact footprint

- Controlled cooling for consistent high product quality

- Fully installed and operational within one week

- Seamless integration into the existing line

This smart solution ensures artisanal taste with industrial efficiency. The client noted Van Abeelen as the only company able and willing, to deliver this within the timeframe and we delivered on that promise.

Looking for a custom made cooling solution?

We are happy to help you find a fast and efficient solution to your cooling challenge. Call +31 (0)161 226 597 or email to [email protected].