Smart Cooling Solution for Bakery Production Line

A major industrial bakery in Waalwijk, part of a leading player in the Dutch bakery sector, needed an efficient solution for their new production line. Every day, thousands of fresh products roll off the line, ready for delivery to supermarkets across the Netherlands.

The challenge: limited space, high efficiency

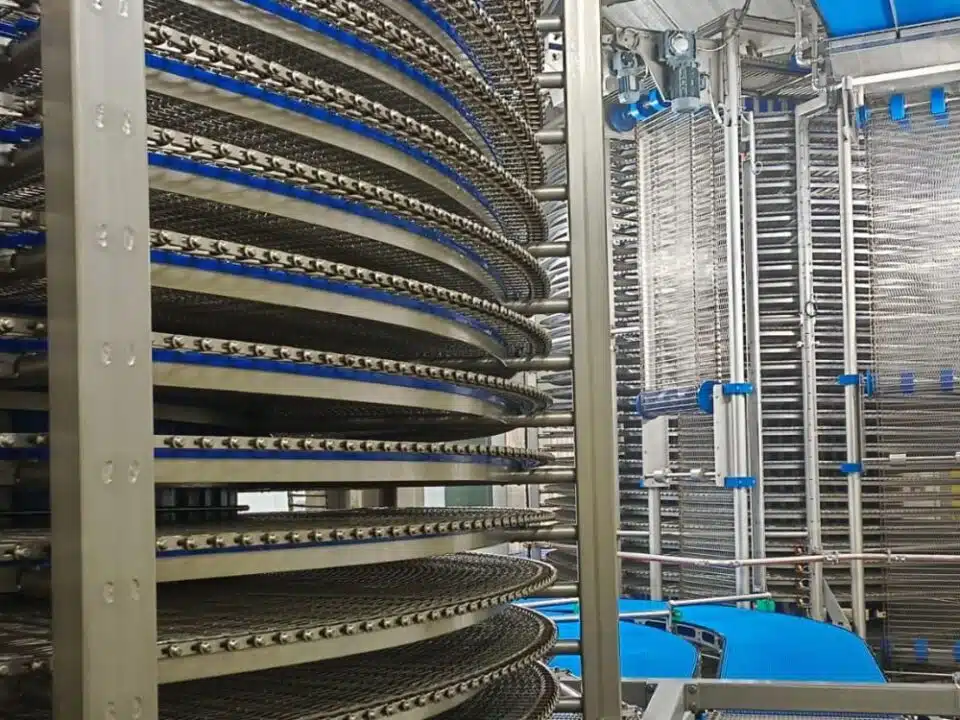

For this new line, three cooling spirals were required to rapidly cool the products right after baking. The challenge wasn’t just the technical specifications, but especially the limited space available at the site and the tight installation schedule. A compact solution and flawless planning were therefore essential.

Custom solution with attention to detail

Van Abeelen delivered three ambient cooling spirals that rapidly and evenly cool the products. Thanks to their compact design, everything could be installed effortlessly within the available space.

Our approach:

- Compact, high-efficiency cooling spirals

- Complete installation within a tight schedule

- Delivery and assembly by an experienced team

Result: satisfied client and a futureproof line

The machines fully meet the customer’s expectations and deliver reliable performance within the production process—crucial when producing large volumes of fresh bread daily. The client expressed high satisfaction with both the quality of the systems delivered and our structured approach. Thanks to this solution, the new production line runs smoothly and is ready for the future.

Need a fast and efficient cooling solution?

From day one, we are happy to help you find a fast and efficient solution for your cooling challenge. Call +31 (0)161 226 597 or email [email protected].