Tailormade Freezing Solution Fish Processing Industry

Maximum flexibility in fish processing thanks to a customized freezing solution

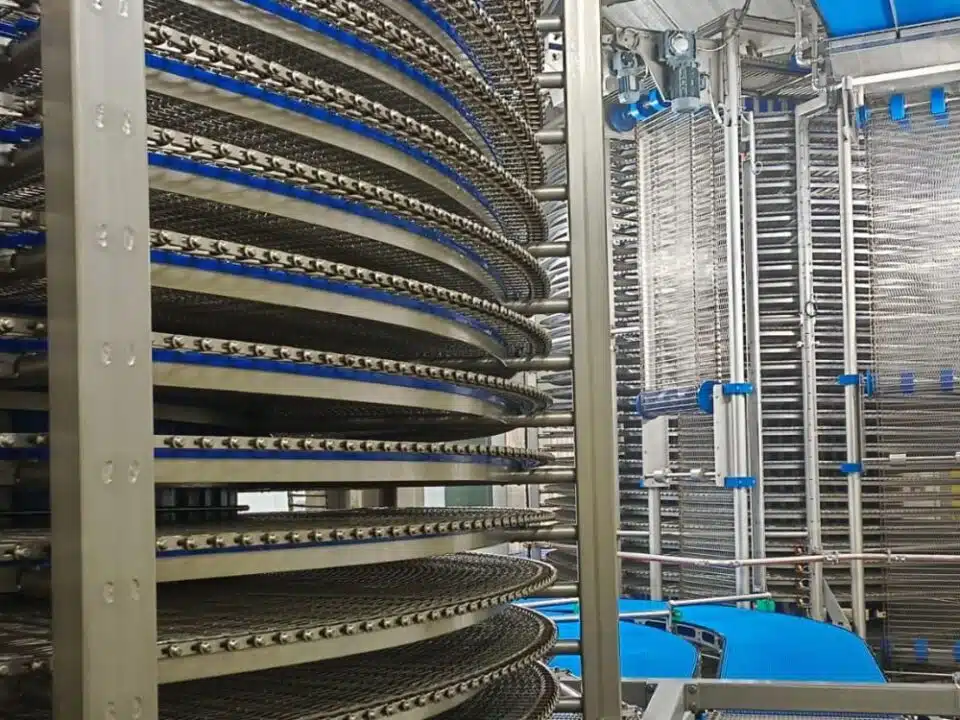

For a fish processor in Urk, specializing in individually freezing fillets and whole fish up to eight kilos, Van Abeelen delivered a fully customized post-freezing process. The project began with a request for a new glazing line, but evolved into a complete optimization of the freezing process.

From client request to future-proof installation

The challenge? A wide variety of fish products, each with unique requirements in terms of temperature, dwell time, and speed. In an existing production environment, it’s essential to design installations that are flexible, energy-efficient, and future-proof. Van Abeelen provided a total solution:

- 3 tunnel freezers (impingement freezers) with a capacity of 30 kW

- 4 plate freezers (horizontal and vertical)

- Optimized glazing process

- Plug & Play CO₂ cooling system with heat recovery

Smart, scalable & hygienic

The freezers were fully custom-designed, tailored to the available space and future expansion plans. Thanks to the combination of freezing and cooling technology, residual heat was cleverly reused for cleaning processes and heating office spaces. Operators have full control over the freezing process via a user-friendly interface, while the hygienic design ensures easy cleaning and long service life. With this installation, the client is ready for a sustainable and flexible future, where customization and capacity go hand in hand.

Looking for a sustainable and flexible cooling solution?

We are happy to help you find a fast and efficient solution to your cooling challenge. Call +31 (0)161 226 597 or email us [email protected].